Features DiStar Mechanic Roller 115-125 - Dust extractor

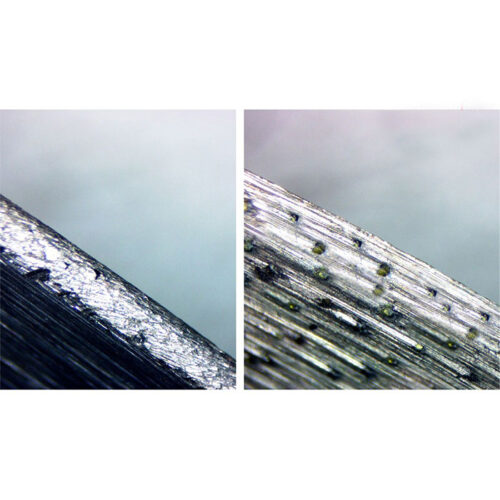

Any diamond blade can become blunt and lose its cutting properties. This is especially common when cutting non-abrasive solid, viscous materials such as porcelain gres, marble, non-abrasive ceramics, etc. Diamond grains destroy and fall out, the machined material is adhered to the bond surface. The temperature in the contact point increases, cutting quality decreases and the blade stops. You risk damaging your tool, which is why the blade must be sharpened. Sharpening means making multiple cutting movements on the whetstone.

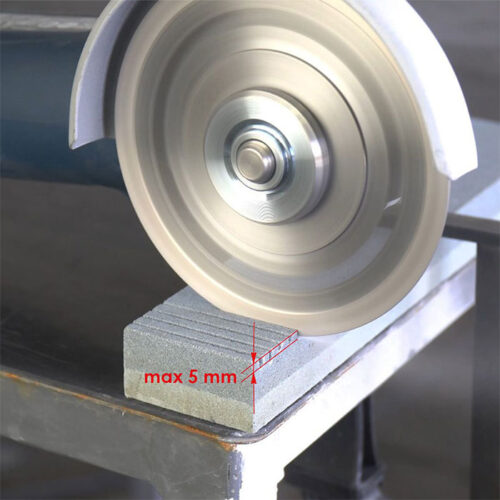

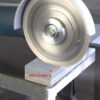

The DiStar Grinding Stone is perfect for sharpening diamond blades. It correctly combines the size and strength of abrasive grains, picked up specifically to sharpen the diamond tool. To do this, make several longitudinal cuts with the dull diamond-containing layer. The blade of the angle grinder makes cuts with a depth of up to 5 mm. The same should be done with blades for the ceramic tile cutter with a depth of up to 10 mm. The duller the blade, the more cuts need to be made. It takes 10-15 cuts to make your blade sharp again.

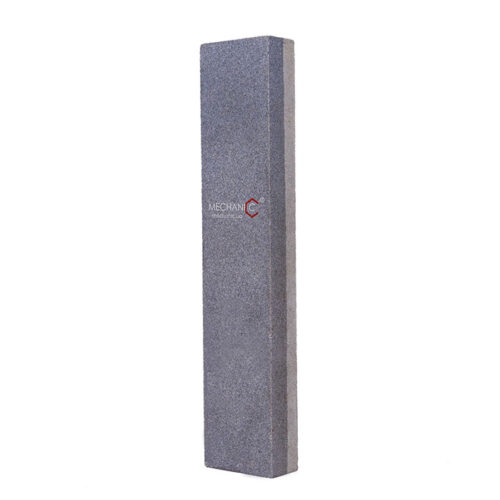

The size of the grinding stone is 250x50x25 mm. It is recommended to clamp the bar while cutting with an angle grinder.

Technical specifications

- Dimensions - 250x50x25 mm

- Brand - Mechanic by Di-Star

Scope of delivery

- DiStar Mechanic Grinding Stone